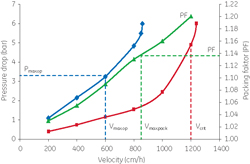

Scale-up of a chromatography process might appear as simply increasing the column diameter to accommodate for the higher quantity of material to be processed, while maintaining the same bed height and flow velocity (i.e., residence time). In practice, however, additional aspects such as method of column packing, hydrodynamic pressure drop, and efficiency of liquid flow distribution need to be considered. A typical problem to be addressed during scaleup is the loss of wall support for the chromatography resin as a result of the large change in aspect ratio, causing larger compression of the resin and an additional hydrodynamic pressure drop. This paper provides a brief overview on the pressure-flow relationship for chromatography resins in packed and compressed beds, and the optimization of a suitable degree of bed compression when developing packing methods for scale-up.